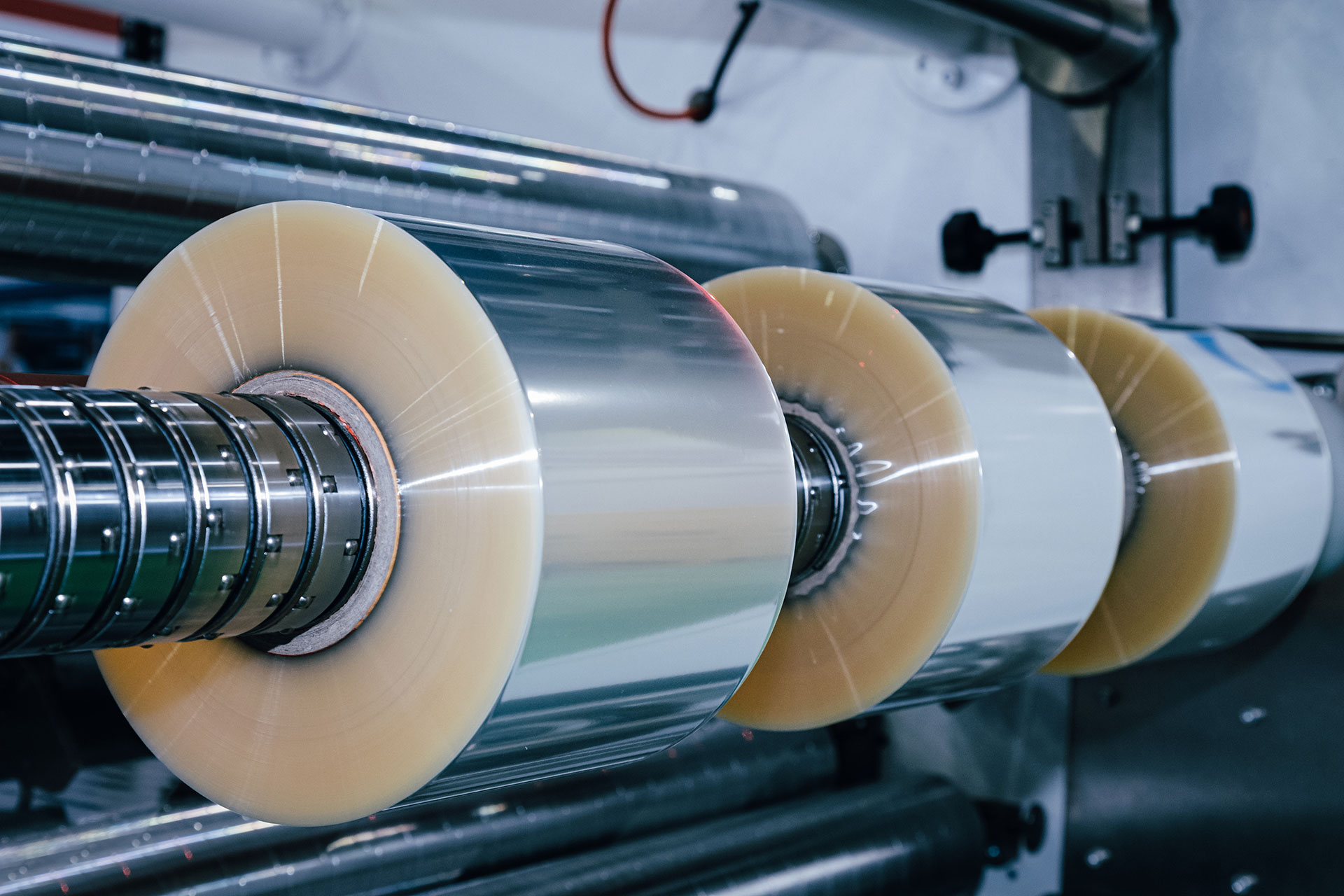

EXTRUSION

During the extrusion process, we convert granules of various raw materials (PE, PA, PP, PET) into a flat film. We go up to 14-layer structures to meet the requirements of each product. Mono structures can be laminated afterwards in order to create multi-layer laminate.

PRINTING

Our reprographics department specialises in the development of the artwork and machine drawings we receive from our customers. When the PDF print image and cromalin proof have been approved, we will keep each print image in your file up to date with printed foil samples, cromalin proofs, machine drawings, ... Together we will decide on intaglio or flexographic printing.

Intaglio printing, rotogravure or gravure is a printing technique in which the design is engraved on a copper printing cylinder. Packas offers both small and larger print runs in a perfect process from design to print and with excellent product presentation. We offer all types of finishes: gloss, matt, paper look, ...

Flexographic printing uses flexible (rubber) inked plates with a slightly raised image to print the image on the film. We can go up to 11 colours and create just about any type of finish here as well.

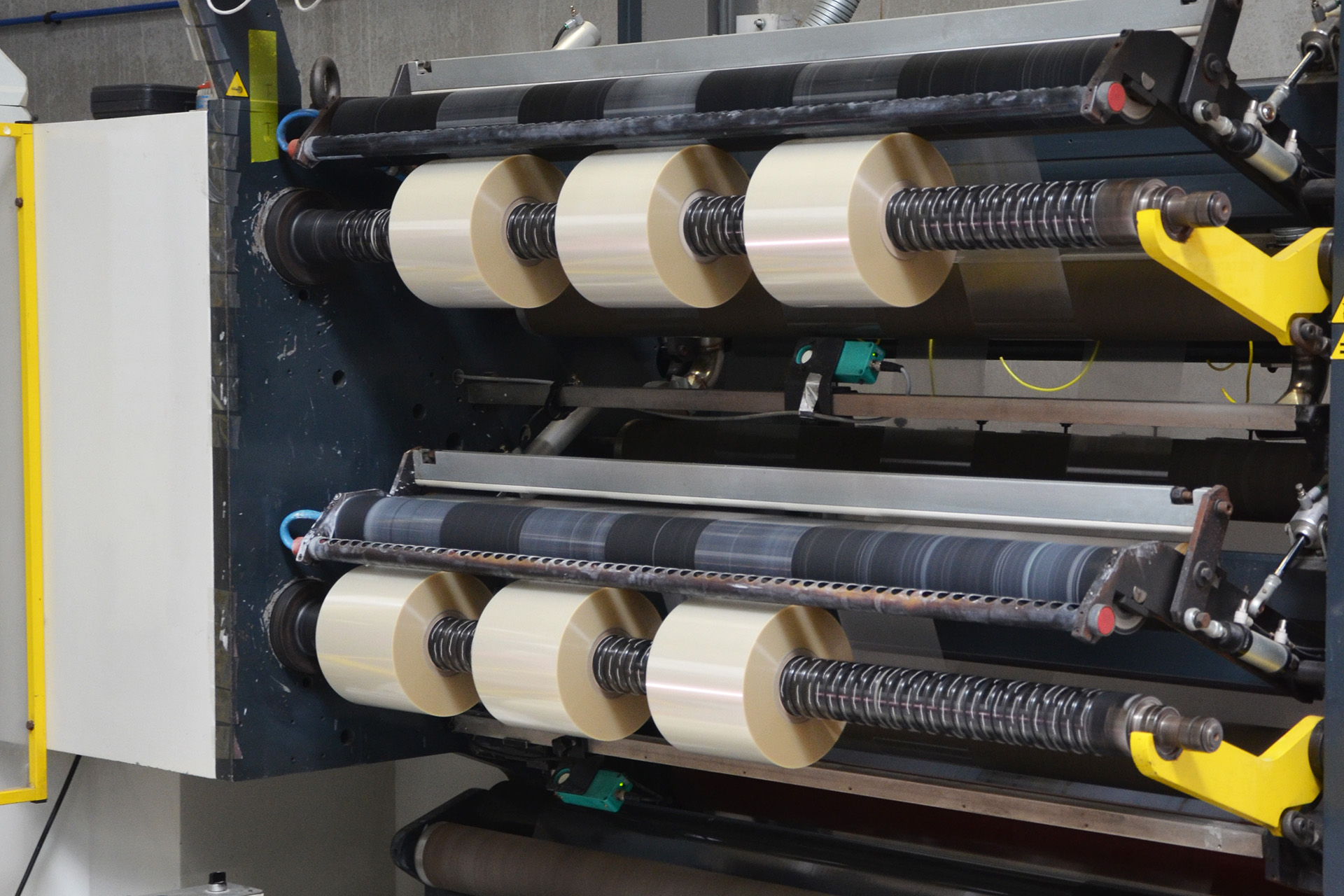

FINISH

Our own slitting department ensures the correct and punctual delivery of your transparent or printed materials. We provide laser micro perforation, hot needle perforation or macro perforation depending on your product.

QUALITY

Our quality team constantly monitors the delivery and receipt of goods. We will assist you with all your questions about legislation, technical data sheets, declarations of conformity and migration. We will guide you through production tests to ensure optimal processing on your machine.